Go to...  | Start A New Topic  | Search  | Notify  | Tools  | Reply To This Topic  |  |

|

Duane, Get the casting number of those heads you are looking at, I would love to find out the info for you. Maybe you can swing a "deal" on those heads, probably the hot rod shop would love to sell an upgrade to the other customer. It sure is an awkward position to lift those heads, hopefully your grandson has vise grips for hands. Oily heavy parts at awkward angles are not easy. I have an engine hoist, and I would consider using that in the RV, with a chain attached to the bolt holes at each end of the head and taking it straight up. I was thinking about that at one point with the 454 work I was doing. Reaching over the control arms did not appeal to me. good luck! Matt 1987 Barth 27' P32 Chassis Former State Police Command Post Chevrolet 454 Weiand Manifold, Crane Cam, Gibson Exhaust | |||

|

3/23 3/23 |

Matt: you are so right, I also have an engine hoist but getting it in the RV would be harder than lifting the heads. Thought the best way is put a 2X4 across the driver and passenger seats, connect a chain to a couple of rocker arm studs and the both of us try to lift them out, one at a time, try the same on the intake manifold first. Will get a photo of the head numbers, for you to check, thanks! 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

3/23 3/23 |

My grandson is strong enough to lift the heads, got the manifold and drivers side head off. The problem was the cylinder that has the stuck valve was not firing at all. Probably my fault, having replaced the spark plugs and wires, one of them is most likely faulty, carbon build up on the valve stem finally froze it closed. the other three on that side look great as do all the cylinder walls. There is a bit of carbon on the piston too. Measured the exhaust temperature a while ago and the driver's side was running cooler than the passenger side. contributed that to the exhaust single routing. Guess that was an error too! Found a set of heads from a 305 engine built in the mid-eighties also has a fresh valve job. The combustion chamber is a bit smaller than the 350 and the intake valve is smaller too. Bolts holes are a total match. A big change is this head takes a totally different spark plug. The guy at the hot rod shop thinks all that will happen is a little higher compression ratio and maybe more low end torque, and a few less horsepower at the top end. Might be a good trade for an RV. The heads are less expensive than having the machine shop fix the problem in the 350 head, not to mention a valve job on both heads. hopefully eliminates my stud pull out problem too. Anybody got any experience with this trade, the hot rod shop guy has always been pretty trustworthy...SOOOOO! 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

Official Barth Junkie |

Generally speaking, increasing compression is a good thing for performance, up to a point. Too high and you'll need high octane gasoline to prevent knocking. Most of the engines before 1972 already had fairly high compression, 9, 10, and 11 to one. Later years were much lower compression, more like 8 to 1. Considering your 350 is an early version, it may already have fairly high compression. If you stay below 9.5 or so you should be able to digest no lead ok. My 400 hp 454 was 9.5 and ran well on regular gas. Smaller valves will restrict top end hp a bit. Not much concern for RV operators. May give slightly better torque. As long as the chambers are not too small and comp ratios are not over 9.5 those heads should be great. Maybe Matt can source those heads and determine comp ratios. Good luck! Have Barth, will travel 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

Dremel tool with a grinder,and a teaspoon will take care of it. Add a teaspoon of displacement from the head for each cylinder and the compression will drop slightly, displacement will increase slightly and if nothing goes wrong you'll breathe a Huge sigh of relief. | |||

|

3/23 3/23 |

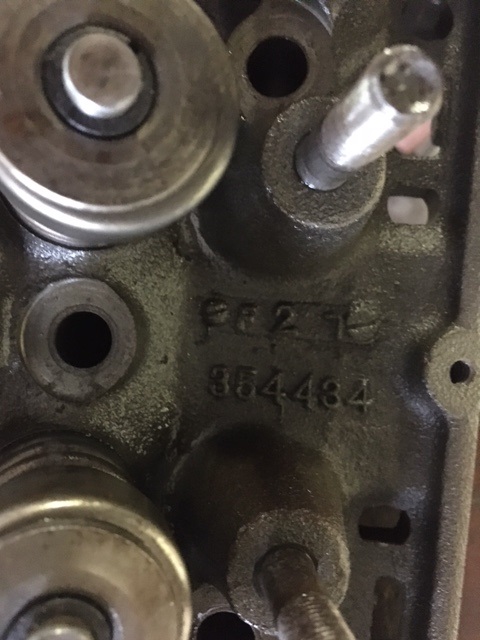

The original compression ratio was 8.7 to 1. When the valve seats were changed to hardened they said it raised it to 9.1 to 1. Going to these heads, the compression ratio might probably stay about the same as the hard seats, at least I assume that because it makes things easier. Matt: Attached it is a picture of the casting number, am very curious what your data has to say about this swap?? This engine was running on crappy old gas without any engine knocking, well ok it did not run like new, but maybe because it was running on 7 cylinders!! Assume 7 cylinders nine bolts and a strong kid, till the passenger side head comes off. Oh Oh did the math and the ratio comes out pretty close to 9.75 to 1. Data shows the 305 had an 8.5 to 1 ratio, Do I dare use 2 head gaskets??? 1971 24 ft Barth Continental P30 chassis 350 engine  | |||

|

|

That casting number, 354434, the magic of Google tells me that it likely came from the 267 V8, and it has 60cc combustion chamber volume. That is going to give a high compression ratio. The port runner volume will be lower too. I am worried that this is not the right tool for the job. Matt | |||

|

Official Barth Junkie |

This leads to some interesting math.... Compression ratio = total volume divided by the chamber volume Total volume = displacement volume plus chamber volume 350 Chev has 4.00in bore and 3.48in stroke: 4.00in x 2.54cm/in = 10.16cm diameter = 5.08cm radius 3.48in x 2.54cm/in = 8.84cm stroke Bore area = 3.14 x radius squared = 3.14 x 5.08 squared = 81.0 sq cm Displacement volume = bore area x stroke = 81.0 x 8.84 = 716.0 cc Compression ratio with 60cc chamber (no gasket) = total volume/chamber volume = (716.0 + 60)/60 = 776.0/60 = 12.9:1 ratio A 1mm gasket is .040in thick = .10cm. Volume added for 0.10 cm gasket = 81.0 x .10 = 8.10cc So, compression ratio with 1mm gasket = (776.0 + 8.1)/(60 + 8.1) = 11.5:1 ratio With 2mm gasket: (776.0 + 16.2)/(60 + 16.2) = 10.4:1 ratio With 3mm gasket: (776.0 + 24.3/(60 + 24.3) = 9.5:1 ratio I don't know what standard gasket thicknesses are available but you will need at least 3mm (.120in) to get to a usable compression range. PS. The above applies only to flat pistons. (Those with domes or recesses must use the volume of the dome or recess in the volume calculations.) 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

Pretty sure a 1/8 gasket would blow out!! Need to verify the combustion chamber volume. Pour in some liquid and measure how much it takes to fill it. Maybe do both the new and old head. Something is amiss here, do the calculation using 305 numbers and one comes out pretty close to an 11.5 ratio the book says this engine was an 8.5 ratio. Wonder if there is some machining to the chamber by the factory. Best do the chamber volume check!! They say they lowered the compression ratio but dishing the pistons. Mine are flat with 4 cut outs I guess for valve clearance. probably only a few cc each. They say a 350 has 70 cc combustion chambers. Do the calculation and the 350 has about an 11.3 ratio and the book says 8.7. MY pistons do not come completely to the top of the cylinders, leaving several thousands gap too! Pretty confused gonna go drink beer!!! 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

Official Barth Junkie |

It is apparent that there is some extra volume. Above calculations assumed pistons flush with cylinder top. If there is a drop to the piston top, you would pick up 8.1cc per 1mm drop... Either way I think 60cc chambers are more matched to the smaller engines. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

Agree, but always a but LoL, if I add another gasket and it is .050 thick this will give almost another 10 cc t0 the combustion area.... even Steven!!!!??? Hee Hee All that is holy says pay the extra money and have the old heads rebuilt!!! If I had faith in the old heads it would be no contest, but do I have faith??? Actually I like the idea of additional low end torque so getting the ratio from 8.7 to 9.5 appeals to me!! 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

3/23 3/23 |

Factory head gasket is .041 compressed. The average piston recess is .020. Making the extra opening .061 or when all calculated 12.25 cc add that to 70 cc combustion chamber making the total 82.25 cc. Making the calculated ratio 9.7 for the 350. Do the same for 60 cc combustion chamber the ratio is 10.9 Add an extra head gasket at .041 thick calculates to 8.25 cc making the combustion area 80.5cc calculates to a 9.92 ratio. Not sure why Chevy says this is a 8.7 ratio engine, wonder what we are missing?? Might be an idiot but am going against all your good advice and gonna use the 305 heads! When the engine knocks and there is less power you can say "I TOLD YOU SO" my guess is the worse that can happen 71 needs higher octane gas. 87 to 89 0r 91...The best it gets more low-end torque!!! A bit less air flow on these low RPM engines is hardly noticeable according to the TV show Engine Masters. BTW thanks for all the help what a fun and informative thread!!! 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

3/23 3/23 |

I had a 69 Plymouth with a 318 that knocked on regular which was specified so I added about 6 ounces of diesel at every fill. Never had any troubles, did have to take a gallon can of diesel when on trips. | |||

|

Official Barth Junkie |

I wonder if GM used less than the full stroke for their volume. Modern engines often have valve overlap between the intake and compression strokes, so at the bottom the intake valve may still be open. As the piston rises the valve closes but some of the compression stroke volume is lost. This is basically what some of the modern engines are doing with variable valve timing to adjust compression on the fly. Rather than stack two gaskets I would shop around for a thicker gasket. Custom shops probably have them. Years ago I recall some builders used thicker gaskets made out of copper. They are less compressible so you had to be really sure the surfaces are very smooth and flat, but they never blew out! Those heads will probably be fine. Like you said, worst case you may need higher octane. With higher compression you will get hp and torque improvement. Raising compression has always been my first choice to increase performance, up to the limit of the fuel octane. 9708-M0037-37MM-01 "98" Monarch 37 Spartan MM, 6 spd Allison Cummins 8.3 325+ hp | |||

|

3/23 3/23 |

Good points on valve lift and stroke, could be that is what they did!! Hopefully this is the stock cam!! The gasket removed is all steel!!! Hopefully 71 will not need the diesel fuel but will keep that in mind!! Bought a set of headers too! Geez would really like this 71 roadworthy, still time for a fall trip or GTG!! 1971 24 ft Barth Continental P30 chassis 350 engine | |||

|

| Powered by Social Strata | Page 1 ... 9 10 11 12 13 14 15 ... 23 |

| Please Wait. Your request is being processed... |

|

This website is dedicated to the Barth Custom Coach, their owners and those who admire this American made, quality crafted, motor coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.

We are committed to the history, preservation and restoration of the Barth Custom Coach.