Barthmobile Portal

fuels and lube engineer wanted...

˙ʎ˙u ןןıq- „ǝןƃuɐ ʇuǝɹǝɟɟıp ɐ ɯoɹɟ pןɹoʍ ǝɥʇ ʇɐ ʞooן ɐ ƃuıʞɐʇ sı ǝɟıן oʇ ʇǝɹɔǝs ǝɥʇ„

|

| 1990 Barth Regis Widebody

8908 0128 40RDS-C1

L-10 Cummins

Allison MT647 Transmission

Spartan Chassis |  | 1991 Medical Lab Conversion

9102 3709 33S-12

Ford 460 MPFI

C6 Transmission

Oshkosh Chassis |

Quick Link: Members Only Link To Send Me A Private Message |

04-25-2011, 06:47 PM

ccctimtationI find the claim hard to believe. In the late 60's we were producing lubes for jet engines and the test speeds were 10K rpm with bearing loading of 50+ lbs/in. The higher the speed the easier it is to produce lubricity. I think the catastrophic failure shown in the pictures was due to random acts of statistics. jmo

04-25-2011, 08:07 PM

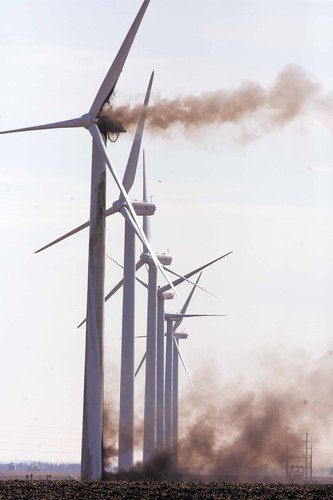

DougZSo much for those things helping to clean up our air.

W4JDZ

04-25-2011, 08:26 PM

RustyAs Tim mentioned, the faster a shaft turns, the easier it is to lubricate.

I have to believe it's a design problem, not a lube issue.

These gearboxes are designed to be as light and compact as possible because they're mounted on top of the pier. Most likely, they were designed with little attention paid either to available lubricant properties or to safety/overload margins.

I think these are 5 MW turbines, which would be in the 7-8,000 HP range, an easy design exercise. The only unconventional parameter is that they're step-up gearboxes, where most gearboxes are for reduction.

Of course the manufacturer wants to attribute failures to the lube, as redesigning and retrofitting the transmissions would be very expensive.

Rusty

"StaRV II"

"StaRV II"'94 28' Breakaway: MilSpec AMG 6.5L TD 230HP

Nelson and Chester, not-spoiled Golden Retrievers

Sometimes I think we're alone in the universe, and sometimes I think we're not.

In either case the idea is quite staggering. - Arthur C. Clarke

It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields

04-25-2011, 09:17 PM

Moonbeam-ExpressI'm sure not a wind turbine expert, but I can web surf. In doing so, I found this passage that makes me think you guys both hit on the problem, albeit rather inadvertently. It's not the high RPM, but the inevitably low wind/low RPM at high load that may be the culprit. Here's the passage of interest.

Many field-operating failures are a consequence of gearbox bearing failure. This type of failure is believed to be directly related to poor lubrication and lack of routine maintenance.

The bearings in the wind turbine gearbox must take extremely high loads, and throughout the gearbox, the bearing performance criteria will be different. In some operating conditions, the requirement is to carry medium-sized loads at low speeds, while elsewhere the bearings need to carry much lower loads but at far higher speeds.

The high-load/low-speed conditions that arise when winds are light can possibly lead to the breakdown of the lubricating film that is normally required for a long bearing life. This has been identified by developers and will be corrected in bearings tests for future wind turbine gear oil specifications.

Formerly: 1997 Barth Monarch

Now: 2000 BlueBird Wanderlodge 43' LXi Millennium Edition DD Series 60 500HP 3 stage Jake, Overbuilt bike lift with R1200GS BMW, followed by 2011 Jeep Wrangler Unlimited,

“I haven’t been everywhere, but it’s on my list.”

04-25-2011, 09:47 PM

RustyThe wind turbine is subject to rotational and thrust loads. Kingsbury thrust bearings are capable of dealing (if spec'ed right) loads produced by ships' engines exceeding 120,000 SHP at speeds of <350 RPM.

Naturally, they aren't cheap.

Designing for rotational loads at varying RPM is also not rocket science.

If the failure is at the turbine, then I agree that poor maintenance or monitoring is a strong possibility. The types of oil suitable for the turbine are both commonly available and relatively long-lived. Of course, that statement assumes robust design and quality construction.

Rusty

"StaRV II"

"StaRV II"'94 28' Breakaway: MilSpec AMG 6.5L TD 230HP

Nelson and Chester, not-spoiled Golden Retrievers

Sometimes I think we're alone in the universe, and sometimes I think we're not.

In either case the idea is quite staggering. - Arthur C. Clarke

It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields

04-25-2011, 10:31 PM

ccctimtationI based my answer about statistical aberrations from the number of successfully functioning mills sighted around the world. When things make news or otherwise draw attention they usually are the exception or it is a slow news day.

04-25-2011, 11:52 PM

RustyI agree. Run a gearbox without proper levels of lube and I can infallibly predict the outcome...

Rusty

"StaRV II"

"StaRV II"'94 28' Breakaway: MilSpec AMG 6.5L TD 230HP

Nelson and Chester, not-spoiled Golden Retrievers

Sometimes I think we're alone in the universe, and sometimes I think we're not.

In either case the idea is quite staggering. - Arthur C. Clarke

It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields

04-26-2011, 09:39 AM

Shadow manI have worked on 2 windmill projects in Wa. I just got the quarterly magazine from the Operating Engineers and they have an article about a windmill job that was done on Ohau. The ones they put in there were 450ft. tall, the ones we did were 350ft. tall. The nacelles,(engine room) on the bigger ones weigh 200,000 lbs. and the rotor/blades weigh 140,000lbs. That is a lot of weight on the bearings up there. I was told that in a high wind runaway situation that the gearboxs can explode and throw parts as far as 3 miles away.

There are a lot of forces acting on these things. This is one of the most interesting jobs that i have ever done and i would like to do a few more before i retire.

Just had to throw this in....

Last week I had a client call me who is a windmill mechanic....I told him I'd call back in 15 minutes and he said to leave him a voice mail..."he'd be outside"....

Glad I work where I work....

04-26-2011, 01:33 PM

Moonbeam-ExpressThe pic of the Ford truck looks like maybe he slid on ice into the blade that was being transported in front. If that blade came down from 300 ft, the hood would be toast!

Formerly: 1997 Barth Monarch

Now: 2000 BlueBird Wanderlodge 43' LXi Millennium Edition DD Series 60 500HP 3 stage Jake, Overbuilt bike lift with R1200GS BMW, followed by 2011 Jeep Wrangler Unlimited,

“I haven’t been everywhere, but it’s on my list.”

04-28-2011, 03:13 PM

Rustyquote:

The nacelles,(engine room) on the bigger ones weigh 200,000 lbs. and the rotor/blades weigh 140,000lbs.

That's only 100T and 70T, far less pressure on bearings than roller mills, or for that matter, diesel-electric locomotive centerplates and axle bearings. It would seem that the turbine hub could be designed with fail-safe self-feathering like turboshaft aircraft propellers.

Rusty

"StaRV II"

"StaRV II"'94 28' Breakaway: MilSpec AMG 6.5L TD 230HP

Nelson and Chester, not-spoiled Golden Retrievers

Sometimes I think we're alone in the universe, and sometimes I think we're not.

In either case the idea is quite staggering. - Arthur C. Clarke

It was a woman who drove me to drink, and I've been searching thirty years to find her and thank her - W. C. Fields

04-28-2011, 04:44 PM

ccctimtationI have passed several of these blades while they were being transported on secondary highways. They are pretty impressive. The first one you see takes a while for your brain to process what is coming at you.

08-10-2011, 01:52 AM

PALEHORSEI would bet there are harmonics at work here ceramic thermal gears cooling units better lubes . I am sure they work it out look at the tech of nuke subs & jet engines they will over come IMHO

08-10-2011, 09:43 AM

Shadow manLooking at those pictures again i wouldn't be surprised if one or two of those had been hit by lightning. When we were doing the ground work for the expansion of the existing site, we had to vacate the area if they detected lightning strikes within so many miles of us.